Labortory

|

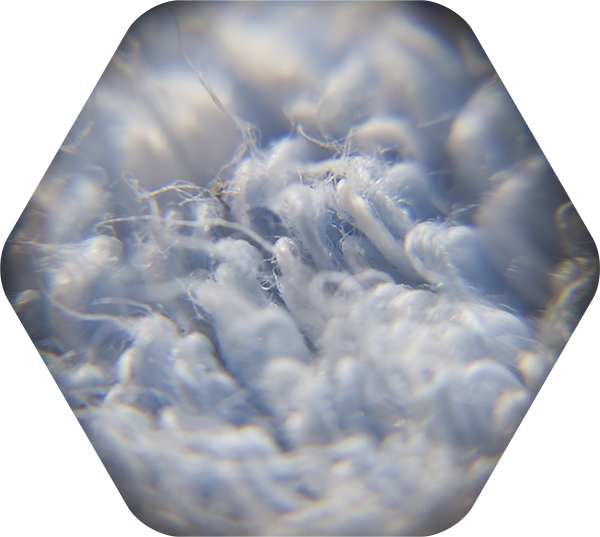

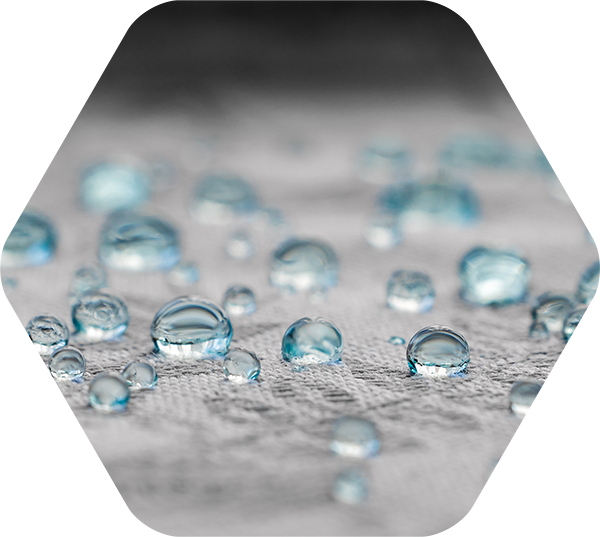

Our own laboratories allow us to control the quality of raw materials sand yarns produced from them at every stage of production. In this way, we can offer our clients products meeting the highest standards of contemporary consumers.

The Quality Control Laboratory tests physicochemical parameters of yarn and its dye absorption. In particular, we determine:

we also determine the moisture content in the polyamide polymer and PBT. At the Quality Control Laboratory, we perform the final assessment of polyamide fibres on the basis of their appearance, woven fabrics and their behaviour upon touch, stretching etc. The Chemical Laboratory is responsible for testing the quality of polymers which are used for yarn production and checking the dye absorption of the finished yarn. At the chemical laboratory, we determine the content of the preparation and identify the type of the polymer in yarn samples. |

|